Boilers are large pieces of energy conversion equipment that use combustion to heat water or other fluids to operating temperatures. Boilers supply steam for heat, energy, and sanitation and are used in personal, commercial, and industrial settings. Boilers are widely used in residential, pharmaceutical, textile, paper, chemical, heavy industry, energy and many other manufacturing fields.

Boilers are special pieces of equipment, adaptable to the application setting and the use of the boiler itself. Industrial boilers are designed to work under pressure from 2.45Mpa to more than 27Mpa, and at the same time withstand temperatures of more than 570℃. Therefore, for the production and manufacturing of boilers, there are extremely strict standards, must importantly “tight seams” at assembly and welding, in order to maximize safety and guarantee performance.

Key Measurements in Boiler Manufacturing

Based on the high demands placed on boiler equipment, there are strict requirements for their production processes. The following three parts of measurement and inspection are very important in boiler production and manufacturing:

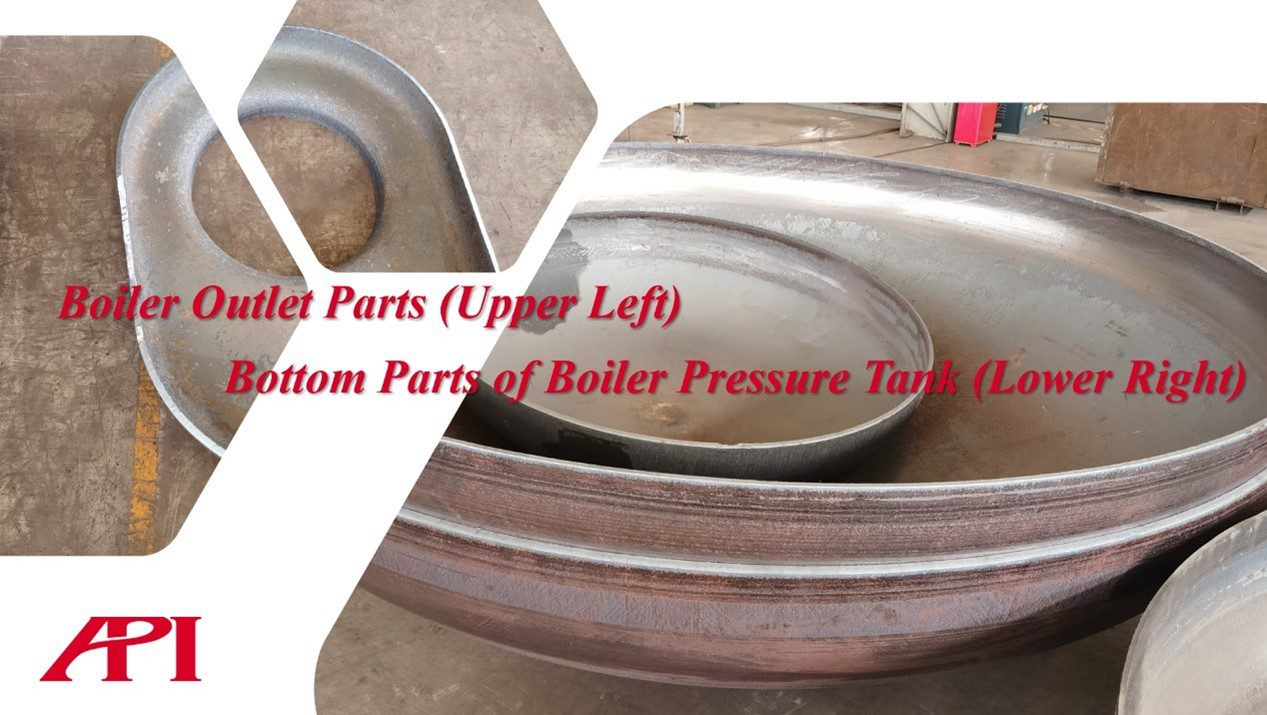

1. Dimensional Parameters of Boiler Outlet and Pressure Tank Bottom

During operation, the boiler outlet and tank bottom are placed under great pressure, so a precise connection between these two parts and the main body of the tank is essential. Measurements of length, width, height, circumference, diameter, lamination surface flatness and other parameters have strict tolerance requirements, generally requiring precision of ±0.3mm. And for special purpose boiler equipment, the requirements can be even more strict.

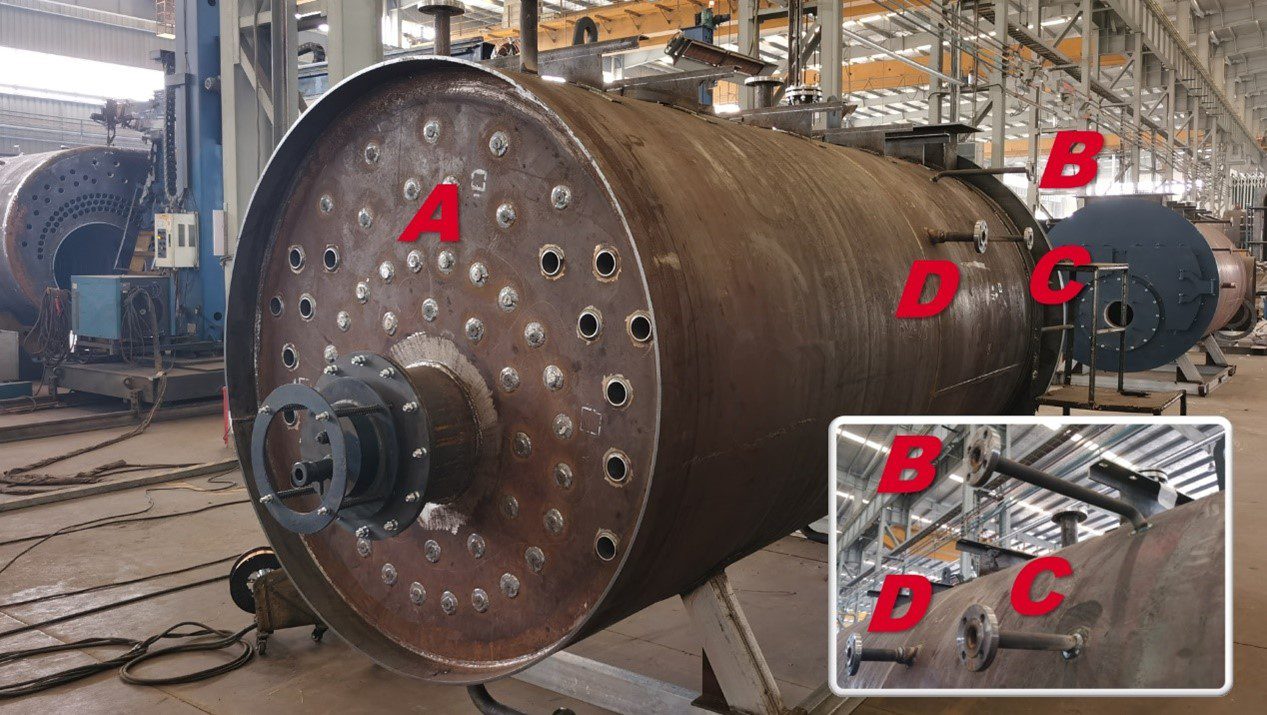

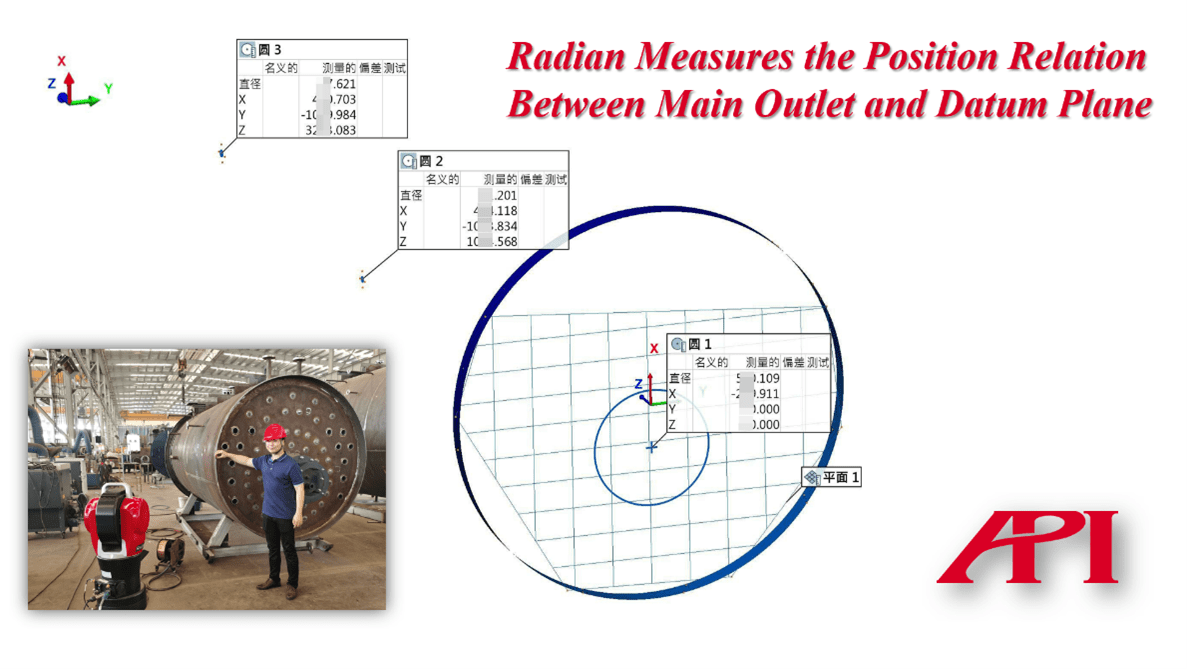

2. Positional Relation Between Datum Plane and Each Pipe Component

In addition to the main body and piping, the boiler may also be equipped with piping components for various functions like additive injection or pressurization. The position of these supporting pipes is very important relative to the position of the datum plane of the boiler. It is necessary to strictly guarantee precise incision position, so as to optimize boiler performance and efficiency, as well as give the best guarantee of safety.

3. Verification of the Overall Quality of the Boiler after Manufacturing

Throughout machining and assembly, the manufacturer will carry out a series of inspections and tests on the boiler, and shape and positional tolerance is the first to be tested. When the overall structural of the boiler has been verified, the following load of tests can be carried out.

API Solution

For the above boiler production and manufacturing measurement tolerances, the use of API’s Radian Laser Trackers can quickly and efficiently perform these inspections and provide pass/fail data reporting for the boiler’s features.

Radian Pro Laser Trackers are the perfect solution for high volume precision measurement. They have a maximum measurement diameter of more than 160m and a measuring accuracy of ADM and IFM lasers for the highest possible accuracy (10 microns +/- 5 microns per meter). With this unique combination of effective working range and precision, Radian Pro can fully meet the testing needs of the shape and positional tolerance in boiler manufacturing.

1. Inspection of Boiler Outlet and Pressure Tank Bottom Parts

As shown in the picture above, once Radian is set up in the appropriate position and reached proper temperature, then measurements can start immediately. When measuring, Radian quickly collects the 3D data of the boiler’s features and feeds this data back to the software to be recorded geometrically. Once several points have been collected, the engineer can select any points needed in the software to construct lines, planes, and bodies, so as to analyze the key features of the part and compare them to CAD data.

2. Inspection of the Position of Each Pipe Component Relative to the Datum Plane

First, the engineer uses an SMR to collect key points on the main body and datum planes of the tank to construct the main body and datum plane’s nominal position in the software. Then, based on these nominal values, the engineer can guide the manufacturers to the proper position for each pipe component.

3. Verify the Overall Quality of the Boiler after Assembly

To verify the overall quality of the boiler after assembly, the engineer uses Radian to collect key points on the boiler and compares the actual and nominal values of these key points in the software. The difference between the actual value and nominal value determines if the boiler is within tolerance and ready for performance testing, or if it needs to be reworked.

Radian Features

In addition to its high accuracy and wide measurement range, the Radian Laser Tracker Series is also compact, flexible, and easy to use. Radian Plus and Radian Core models can achieve completely wireless measurement (through battery power & wireless data transmission), completely avoiding troubles caused by cables. Radian Laser Trackers can work in limited space, and can always be mounted in the best location for measurement.

In addition, when measurement of hidden points is needed, the vProbe wireless smart probe can be used instead of a traditional SMR. By touching the hidden points with the probe, places out of the tracker’s line-of-site can be easily measured and inspected without moving the Laser Tracker. API’s Radian Laser Trackers can fully meet the measuring requirements in boiler manufacturing. Accurate and efficient, Radian provides the maximum guarantee for the quality and safety of boiler manufacturing