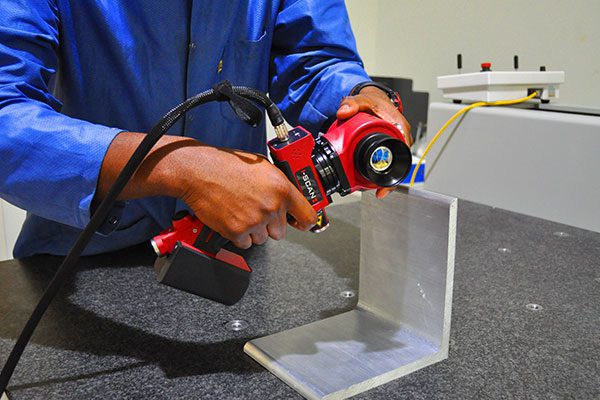

API iSCAN

HANDHELD SCANNING

IFM-BASED

ACCURACY

1.2 KG

WEIGHT

32,000

POINTS/SECOND

360°

SWIVEL HEAD

SCAN ANY SURFACE

IFM-BASED ACCURACY

360° TRACKING

CONTACT

Phone: 1-800-537-2720

FEATURES AND BENEFITS

ACCURACY

IFM based precise measurement for use in applications that include fixture inspection, gap and flush inspection, and reverse engineering.

SCANNING PERFORMANCE

Capable of scanning complex surfaces like high gloss or high contrast areas.

COMPACT SOLUTION

A lightweight 3D scanning system that is easy to transport and use.

360° CONTINUOUS TRACKING

The iScan’s swivel head allows for continuous movement while being in line of sight with a laser tracker.

ERGONOMIC DESIGN

Easy to hold and operate during measurement of cavities, hidden angles and curves.

TECHNICAL SPESIFICATIONS

175mm STAND-OFF

| 7M | 15M | ABOVE 15M | |

| Spatial Length (SLU) | ∓ 50 μm | ∓ 80 μm | ∓ 20 μm + ∓ 4 μm/m |

| Sphere Radius (RU) | ∓ 50 μm | ∓ 75 μm | ∓ 30 μm + ∓ 5 μm/m |

| Surface (SrU) | ∓ 100 μm | ∓ 110 μm | ∓ 80 μm + ∓ 2 μm/m |

SPATIAL LENGTH UNCERTAINTY (SLU)

SLU is the deviation between a length measured with the iScanTM (in a static orientation) its nominal value.**

SPATIAL RADIUS UNCERTAINTY (RU)

RU is the deviation between a measured sphere’s radius and its nominal value.**

MEASUREMENT UNIT SPECIFICATION

SLU and RU are further specified as a function of the distance between the laser tracker and the measured surface.

*These values represent the Maximum Permissible Error(MPE) between a verified Scale Bar and the expected performance of the instrument.

*Nominal Values are established by the Laser Tracker.

APPLICATIONS

Integrated with an API 6DOF Laser Tracker the innovative API iScan™ wireless handheld blue laser line scanner offers a fast, accurate and more productive solution to generate component point-clouds. Digitizing rates of up to 200,000 points/second and capable of scanning both shiny and dark surfaces iScan™ features 360° yaw and roll to achieve infinite sensor positioning. Weighing just 1.2KG its simple one-button operation provides effortless scanning functionality and also offers tactile probing providing even greater tracker measuring flexibility. Applications include:

- Part Inspection

- Cavity Probing

- Quality Measurement

- Jigs, Fixture & Tooling Inspection

- Reverse Engineering

- Surface Scanning

- Precise Measurement