Laser Tracker Certification

Laser trackers have become the measuring tool of choice for large volume dimensional metrology applications within the aerospace, ship building, terrestrial transportation, and power generation industries. A laser tracker is a portable coordinate measuring system that tracks a moving target reflector and measures the position of the target in spherical coordinates (r, θ, φ). The metrological performance of a laser tracker is influenced by many factors including: compensation for atmospheric effects, thermal expansion of the instrument and its mount, thermal distortion of the workpiece or artefact being measured, the wavelength of the laser radiation, the internal alignment of the gimbal axes, and the linearity and alignment of the internal angular measuring scales.

The most important of these potential error sources, which fundamentally limits the achievable uncertainty, are the internal mechanical and optical alignments and the quality and alignment of the angular scales.

As with any metrology instrument, a laser tracker needs to undergo periodic performance verification.

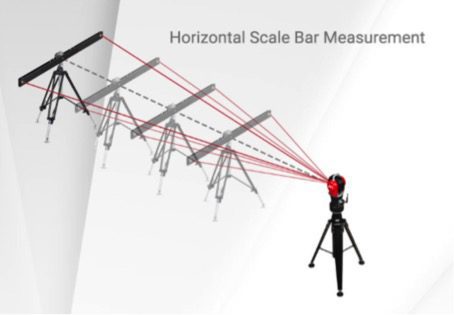

ASME B89.4.19-2006 is one of the established standards used to verify the metrological performance of laser trackers. The main test relies on measuring a known reference length in a variety of configurations and ranges and comparing the observed error with the specified maximum permissible error (MPE) defined by the laser tracker manufacturer.

In the Length Bar Test, the main artifact (or reference length) is specified to be at least 2.3 m long, and the test is performed with the scale bar positioned at various distances (specified by the manufacturer) away from the tracker, typically 2m, 5m, 10m, 20m, etc. The In-Line Distance test sees a target reflector positioned at a defined distance from the tracker and measurements taken.

API is A2LA certified to perform laser tracker accuracy certification of all brands to ASME B89.4.19-2006 standard. These certifications are available to be scheduled at API’s headquarters in Rockville, MD and at the API Services Lab in Newport News, VA.

INTERESTED IN OUR METROLOGY PRODUCTS OR SERVICES? CONTACT US HERE.