API SERVICES ARE AVAILABLE WORLDWIDE

REVERSE ENGINEERING

Whether for global manufacturers or small custom shops, API’s measurement expertise, combined with advanced metrology equipment, can execute convenient and fast reverse engineering projects. Our Laser scanning services can create data from an existing part or compare captured data to a CAD model. Reverse engineering services include scan as-built parts to creation of a 3D digital point cloud and CAD Model.

API reverse engineering service utilizes advanced equipment and software. Your facility or ours. API has perfected an efficient reverse engineering and modelling process.

“Review your reverse engineering project with the experts.”

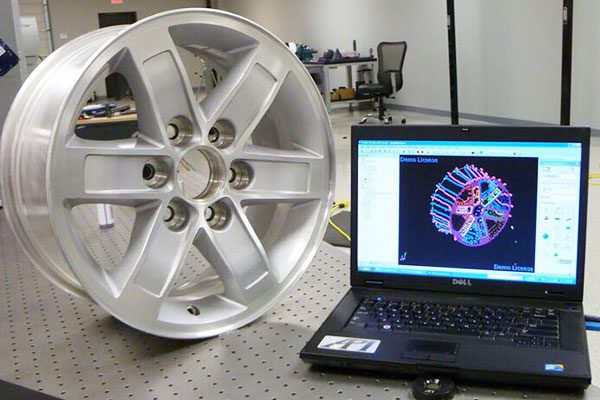

LASER SCANNING

Whether your requirement is a CAD model of a prototype part or designing a part within existing part constraints, API’s laser scanning services can provide a digital point cloud of your part. API utilizes a range of non-contact scanners for both large and intricate parts providing the necessary detail and accuracy for your project. We can laser scan your parts at our facility or attend your location with our equipment if your part is large or of a highly sensitive nature.

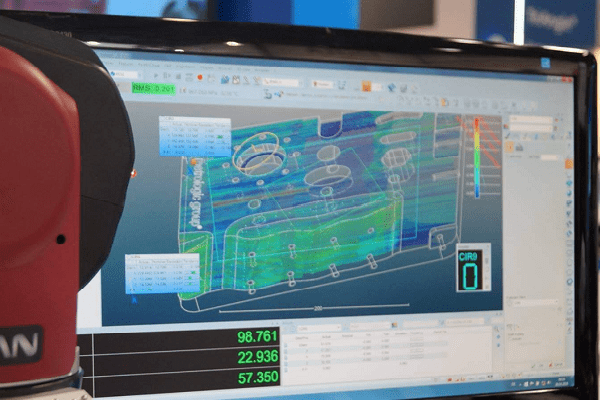

CAD COMPARE

API technology is able to take the ‘as-generated’ point cloud and direct compare against a nominal CAD model of the scanned part. API technicians can provide a colored topographical 3D report showing quantified deviations in the scanned model which can be presented in free form or with reference alignment conditions. Geometry extraction with actual versus nominal reporting.

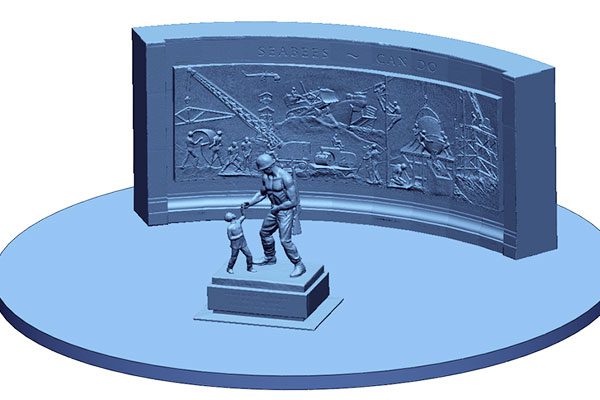

3D MODELING

Utilizing reverse-engineering software, API technicians can extract optimal CAD entities including curves, surfaces, and prismatic features from the generated polygonal models of reverse engineered digitized parts providing a professional part CAD modeling solution. Typical applications include prototype parts, legacy part replication, product benchmarking and historical documentation.

REVERSE ENGINEERING

Whether for global manufacturers or small custom shops, API’s measurement expertise, combined with advanced metrology equipment, can execute convenient and fast reverse engineering projects. Our Laser scanning services can create data from an existing part or compare captured data to a CAD model. Reverse engineering services include scan as-built parts to creation of a 3D digital point cloud and CAD Model.

EXPERIENCE MATTERS

API Measurement Services are active globally across all manufacturing industries with specific measurement and calibration solutions per sector. API calibration equipment and services assist in improving manufacturing processes through the calibration of machine tools and the accuracy enhancement of industrial robots, both at original equipment manufacturers, and end users. API contract inspection services offer on-site prototype, first article, production measurements and a portfolio of reverse engineering, laser scanning and modeling services. API laser tracker inspection, alignment and measurement services, along with tracker rental programs, are active in the construction of new manufacturing facilities whether associated with building construction, equipment installation or aiding pre-production product manufacturing.

- • Aerospace

- • Automotive

- • Heavy Machinery

- • Energy

- • Military & Defense

- • Manufacturing

- • Transportation

- • Machine Tools

- • Industrial Robots

API Measurement Services offer on-site prototype, 1st article and production measurements. Our suite of engineering services include reverse engineering and modelling, inspection and alignments, calibration services.

A2LA ISO 17025 certified.