API Services Creates “Jig Reference System” for Aeronautical Engineers, Inc. Assembly Fixture

Cargo doors on modern large aircraft are massively complex projects, requiring exacting production and precise assembly of hundreds of small parts. To keep all of these parts in place during assembly (and ensure accurate alignment), large assembly fixtures are required. The fixtures themselves need to be designed and produced to the same demanding tolerances as the cargo doors they will help assemble. When Aeronautical Engineers, Inc. (AEI) in Miami, FL had a cargo door assembly fixture that was built with no specific tool design, they turned to the experienced team of expert metrologists at API Services to help verify the fixture and identify areas of rework. API Services was able to:

- Identify “as-found” errors in location, flexing, squareness, and concentricity of as much as .188”

- Create a “jig fixture system” to correct these errors and optimize future applications

- Reduce all of the above errors by at least 75%

Aerospace manufacturing designs vary wildly from one aircraft to the next, but each one features thousands of complex parts that must be meticulously machined and aligned to one another to create a final assembly that matches the original design. Located in Miami, FL, AEI has been performing this kind of work for decades. Formed in 1958, AEI is the oldest conversion company in existence today. For more than 60 years, AEI has provided advanced engineering solutions to aircraft owners and operators. As a global leader in passenger to freighter conversions for a wide array of aircraft, AEI has developed over 128 Supplemental Type Certificates (STCs), and more than 490 aircraft have been modified with AEI STCs – more than any other conversion provider.

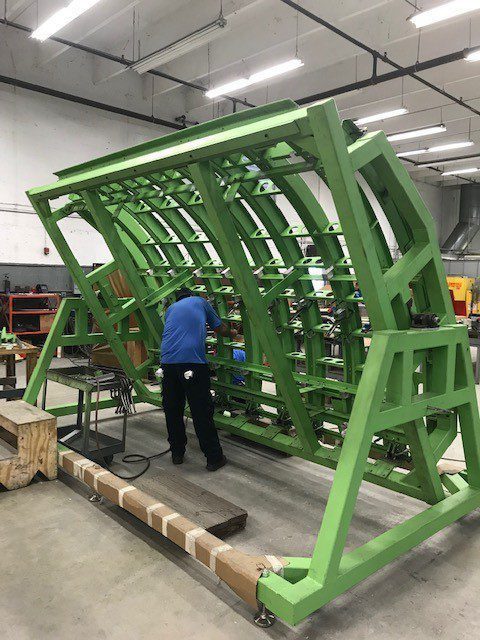

David Murphy, Director of Quality at AEI, had a cargo door assembly fixture that was built with no tool design, and he needed it to locate, hold, and assemble a multitude of individual parts to create a cargo door assembly for the Boeing 737-800 aircraft. The engineered design of the cargo door assembly was shown to be very complex, and the fixture was necessary to hold well over 100 individual parts in critical locations to accurately create this assembly. David contacted API Services to certify this assembly fixture and perform any necessary re-work to optimize its performance for the Boeing cargo door.

MSP Found and Corrected Errors in Location, Flexing, Squareness, and Concentricity by 75%

After determining the scope of work, the team at API Services went onsite with the state-of-the-art Radian Laser Tracker to verify the fixture. Inspecting the fixture, as it was built, API found critical locators at the lower side of the door to be 0.040” out of tolerable position. The locators holding the periphery of the door frames were found to be 0.188” out of square. Also, the fixture had to be rotated on trunnions to complete assembly work, and the trunnion centers were found to not be concentric as necessary. This error caused the entire fixture to twist 0.065” out of tolerance when rotating. There were also critical locators missing from the fixture which the fixture builder was unsure how to manufacture and install.

The number and severity of problems with the assembly fixture meant that re-work was going to be necessary bring the fixture back into specification. To solve as many of the problems as possible at once, API Services proposed adding a “jig reference system,” which would allow for the fixture to be built from any position. This reference system would also correct the concentricity of the trunnion centerline, which would eliminate the fixture’s flex issues during rotation, and re-locate the individual locators to match the engineered design of the cargo door to within acceptable tolerances. API Services also provided solutions for adding the design and manufacture of the missing locators to complete the fixture.

Across more than seven weeks of support, API Services was able to create the complete “jig reference system” and include the values (in aircraft coordinates) in a final report to AEI. After working with the concentricity of the trunnion centers, they were able to correct the fixture flex to be within 0.006”, which was acceptable to AEI. They were able to then correct mis-locations of individual locators, setting and pinning in place using steel dowel pins, positioning all locators to 0.010” or less as per engineering design standards. Once all of these corrections had been made, API Services verified the new values of the assembly fixture, assisted AEI with the designs of the lacking fixture locators, and made recommendations to streamline and facilitate the manufacturing process of the cargo door assembly. API provided all locator values, with tolerances, in a complete inspection report as required by AEI.

API Service’s unmatched experience with Aerospace manufacturing and jigs, fixtures, and tooling, combined with their dedicated customer support, allowed them to provide a complete solution for AEI. The team went beyond simple error compensation to create a reference system and best practices to optimize AEI’s work on future door assembly applications. The global team at API Services are the experts in applications across all industries and with API’s world-class metrology equipment. They are standing by to assist your manufacturing needs.

Links from this article: