WIRELESS BALLBAR

PERFORMANCE VERIFICATION

8 HOUR

BATTERY LIFE

1,000 HZ

SAMPLING RATE

BLUETOOTH

CONNECTIVITY

0.075 MM

RESOLUTION

EFFICIENT ANALYSIS

ERROR DETECTION

REDUCE COST

CONTACT

Phone: 1-800-537-2720

FEATURES AND BENEFITS

WIRELESS OPERATION & EXTENDED BATTERY

Connect wirelessly to the API VeriComp Software with Bluetooth connectivity and 8 hour rechargable battery.

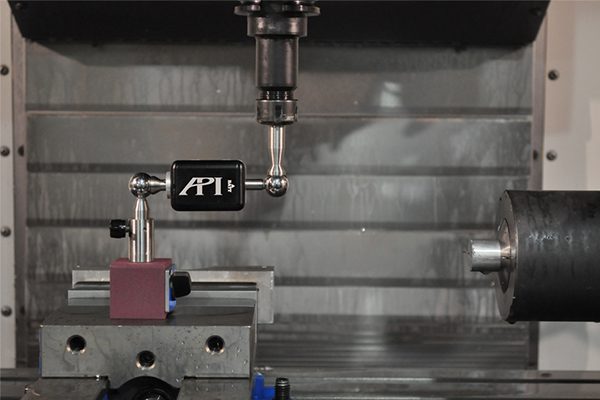

POWERFUL DIAGNOSTIC TOOL

Capable of measuring lathes or CNC machines at any sweep angle within the 360o circular path to identify and diagnose servo and mechanical errors.

EARLY DETECTION TOOL & MAINTENANCE

Add Ballbar Performance Verification to your regular maintenance cycle to identify and predict machine errors, reducing scrap, setup times, and production costs.

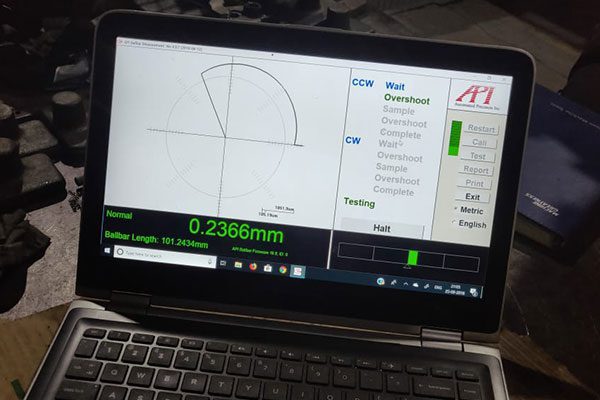

EASY-TO-USE SOFTWARE

Perform multiple measurements in a single, simple setup to identify all machine servo errors with an intuitive analysis.

COMPLETE DIAGNOSTIC PACKAGE

Complement your API suite of products with the XD Laser and Spindle Analyzer for a complete CNC solution.

TECHNICAL SPESIFICATIONS

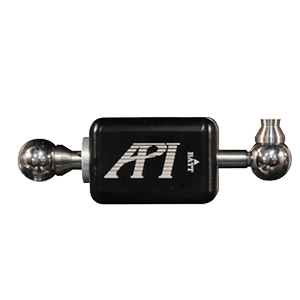

WIRELESS BALLBAR SPECIFICATIONS

| Parameter | Specification |

| Connectivity | Bluetooth |

| Battery Life | 8 hours (Rechargeable) |

| Resolution | 0.075 μm (3.0 μin) |

| Accuracy | ± (0.5+0.1%L) μm (20 μin) |

| Range | ± 1.5 mm |

| Sample Rate | 1,000 Hz |

| Dimensions | 102.6 mm x 37.3mm x 37.3 mm (4.0 in x 1.5 in x 1.5 in) |

APPLICATIONS

API’s wireless Ballbar easily measures CNC machine performance to predict and diagnose servo errors and path deviations. The Ballbar is a simple, cost-effective solution that is designed to improve overall machining quality and reduce costs to all end users. Measurements include:

- Backlash

- Squareness

- Stick-Slip

- Servo Lag

- Scale Mismatch

- Machine & Servo Vibration