API SERVICES ARE AVAILABLE WORLDWIDE

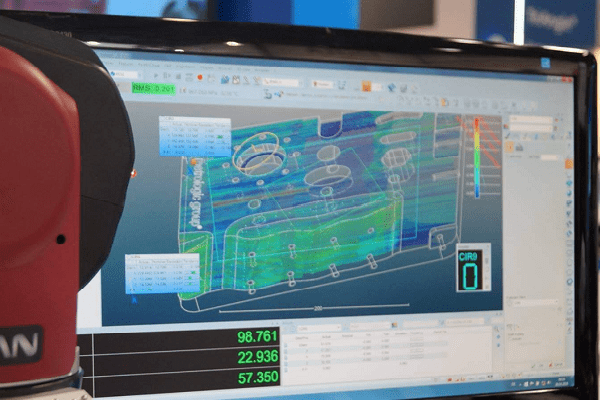

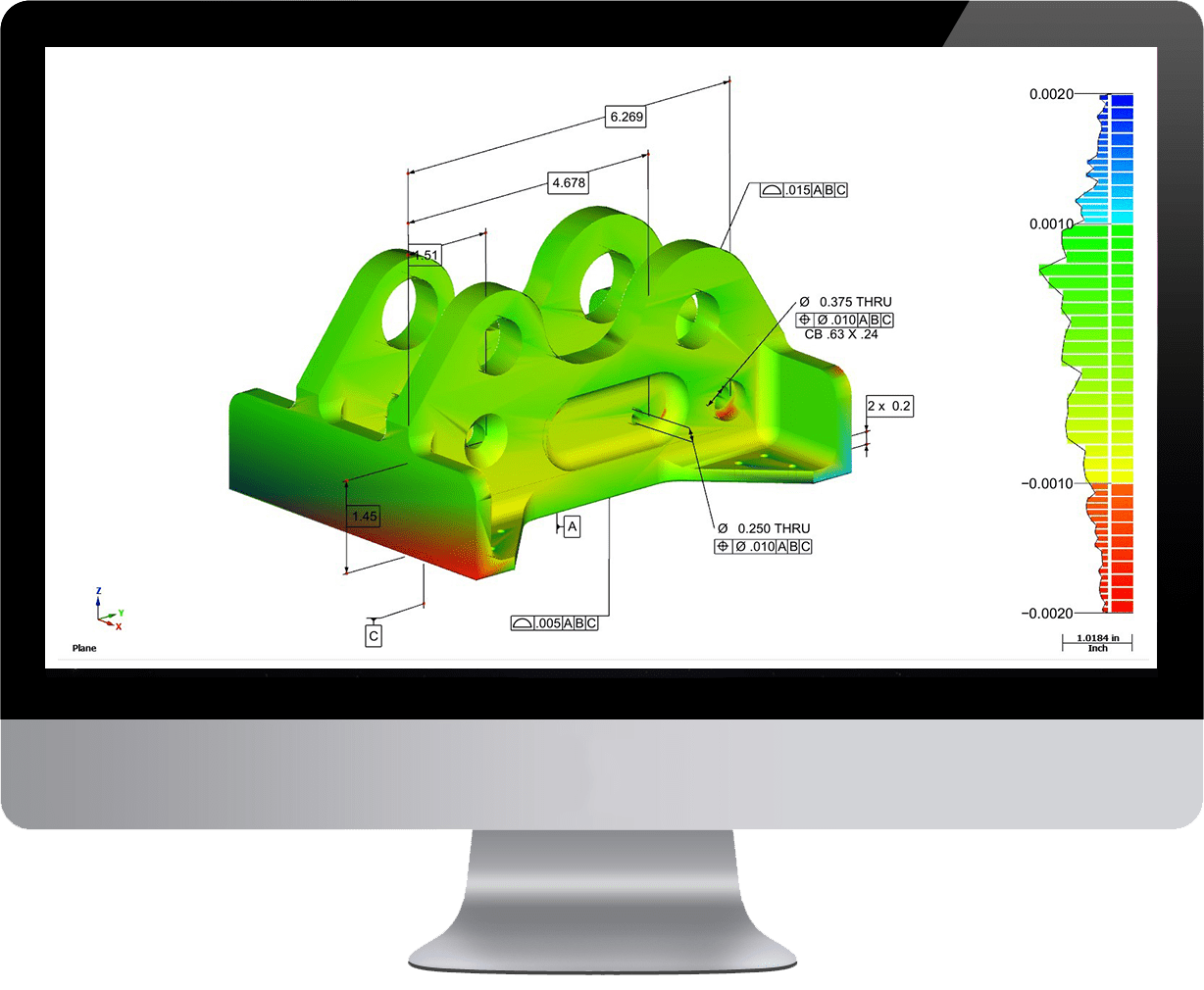

FIRST ARTICLE INSPECTION

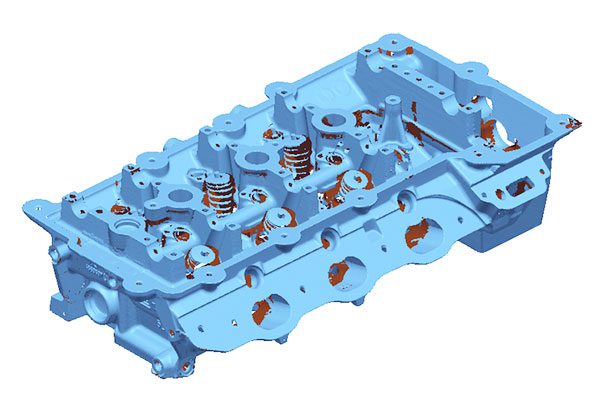

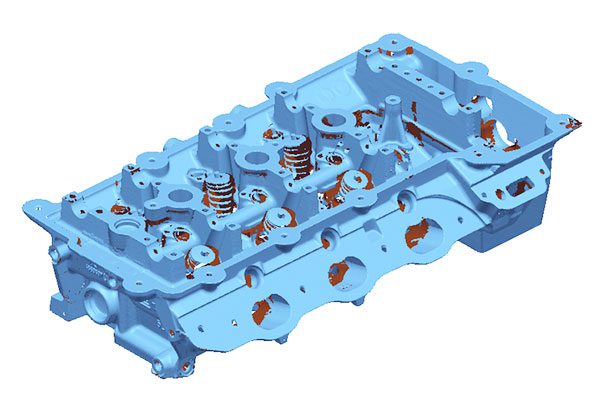

API’s, on-site, first article measurement services provide inspection data on parts and assemblies with direct comparison against CAD models or drawings. Generated 3D measurement data from our portable metrology equipment and 3D scanners offers a comprehensive analysis of the physical part under measurement. Inspection reports can include 3D color maps or generated 3D models for detailed computer analysis.

API reverse engineering service utilizes advanced equipment and software. Your facility or ours. API has perfected an efficient reverse engineering and modelling process.

“Review your reverse engineering project with the experts.”

MANUFACTURING

Ensuring that a manufacturing process, for a part or assembly, will yield quality product is a critical step before commencement of further production units. API’s rapid-response measurement services team can attend site to validate a part conformance, using our standardized 1st article inspection process, validating against design intent. API can also validate manufacturing equipment and machining, stamping, molding, fabricating, 3D printing and additive manufacturing processes.

TOOLING BUY-OFF

Third party supported ‘buy-off’ of tooling and equipment from external vendors is crucial to validate performance before acceptance. API measurement services can support your efforts and bring an accredited judgement to the decision process. API can provide support at the vendor location and subsequently at the final installation site ensuring full data correlation. In addition to 1st article inspection we can also provide in-depth process capability studies.

PROCESS VALIDATION

Whether it’s a new manufacturing facility, production line, manufacturing process being validated API measurement services can support your on-site inspection and alignment needs. As a technology leader in the supply of laser based measurement equipment our technicians are equipped with the very latest measuring equipment available from laser trackers to portable arm CMMs integrated with tactile and laser scanners and laser interferometers.

DIAGNOSIS AND TROUBLESHOOTIN

When manufacturing quality is not being delivered as expected the API measurement services team are available to perform on-site part measurement and equipment validation to troubleshoot and diagnose the issues. Our experienced team bring an independent and unbiased approach to identifying root cause and recommending and action plan to go forward. API has experience across all manufacturing sectors and processes.

EXPERIENCE MATTERS

API Measurement Services are active globally across all manufacturing industries with specific measurement and calibration solutions per sector. API calibration equipment and services assist in improving manufacturing processes through the calibration of machine tools and the accuracy enhancement of industrial robots, both at original equipment manufacturers, and end users. API contract inspection services offer on-site prototype, first article, production measurements and a portfolio of reverse engineering, laser scanning and modeling services. API laser tracker inspection, alignment and measurement services, along with tracker rental programs, are active in the construction of new manufacturing facilities whether associated with building construction, equipment installation or aiding pre-production product manufacturing.

- • Aerospace

- • Automotive

- • Heavy Machinery

- • Energy

- • Military & Defense

- • Manufacturing

- • Transportation

- • Machine Tools

- • Industrial Robots

API Measurement Services offer on-site prototype, 1st article and production measurements. Our suite of engineering services include reverse engineering and modelling, inspection and alignments, calibration services.

A2LA ISO 17025 certified.