Unlock Peak Precision with Advanced MTC Calibration

In the world of high-precision manufacturing, the accuracy of your CNC machinery is directly tied to your bottom line. Over time, every machine tool experiences wear, thermal drift, and geometric errors that can lead to costly scrap and rework. This is where MTC Calibration (Machine Tool Calibration) becomes essential. As demonstrated in the featured video, modern calibration isn’t just about checking linear positioning; it requires a comprehensive analysis of the machine’s entire volumetric performance. For manufacturers aiming to maintain tight tolerances and ensure repeatability, adopting a robust MTC strategy is the only way to guarantee that every part produced meets the most rigorous standards.

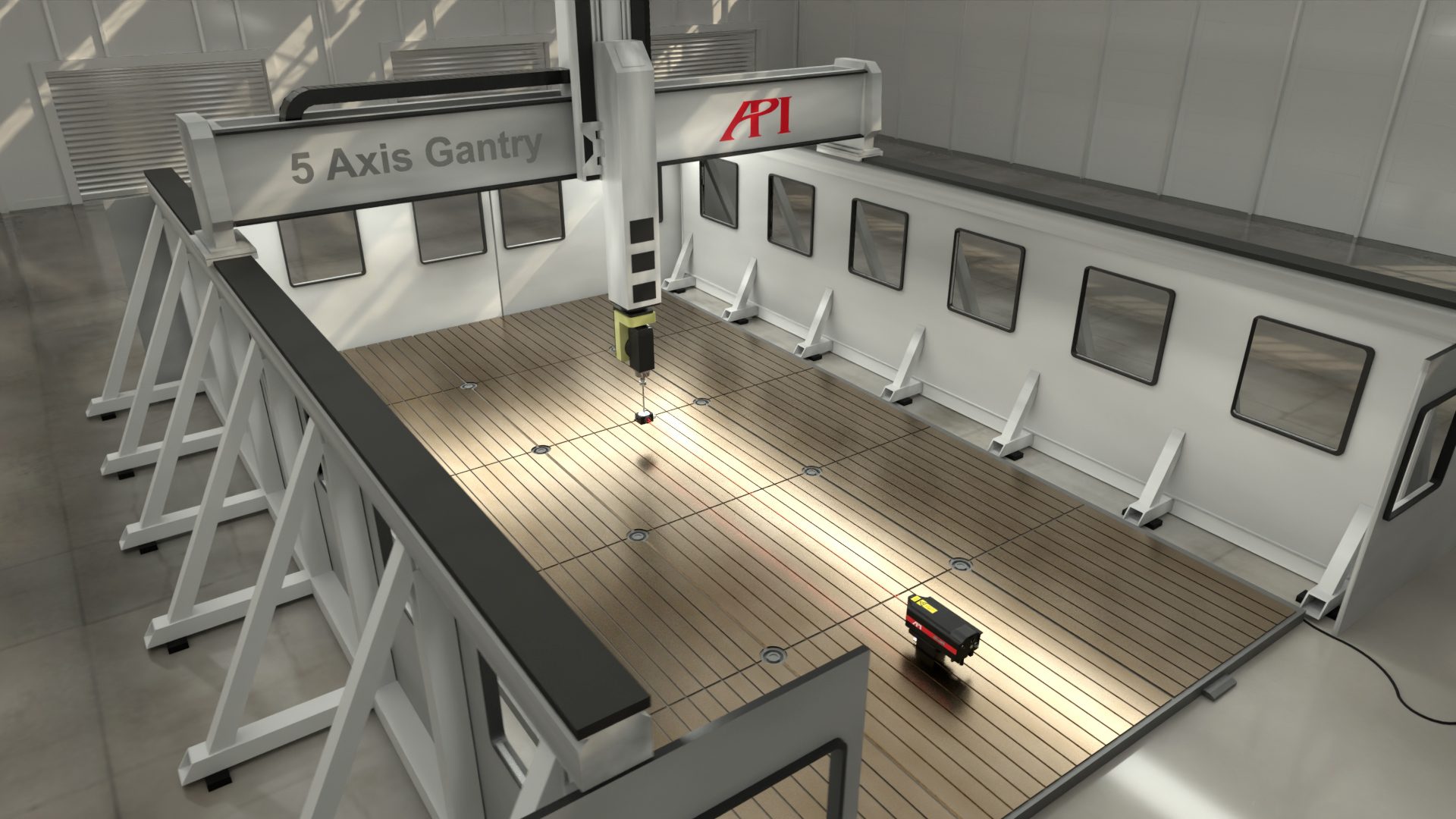

The XD Laser Advantage: Eliminating Complex Re-Alignments

The video highlights API Metrology’s solution to these challenges: the XD Laser. Unlike traditional interferometers that measure one error at a time, the XD Laser is designed to handle MTC Calibration by measuring all six degrees of freedom (6DoF) simultaneously. This means that in a single setup, it can capture all 21 potential error parameters—including linear positioning, straightness, pitch, yaw, and roll. This capability is a game-changer for shop floors, as it eliminates the need for multiple re-alignments and complex equipment changes, ensuring that the calibration process is as precise as it is comprehensive.

Maximize Profitability via Efficient MTC Strategies

Perhaps the most significant advantage discussed is the dramatic efficiency gain. By capturing all error data in one pass, the XD Laser can reduce machine downtime by up to 80% compared to conventional methods. This speed allows facilities to perform MTC Calibration more frequently without disrupting production schedules. Whether you are commissioning a new machine or performing preventative maintenance after a crash, utilizing advanced tools like the XD Laser ensures your equipment is fully optimized, ultimately boosting your manufacturing throughput and profitability.