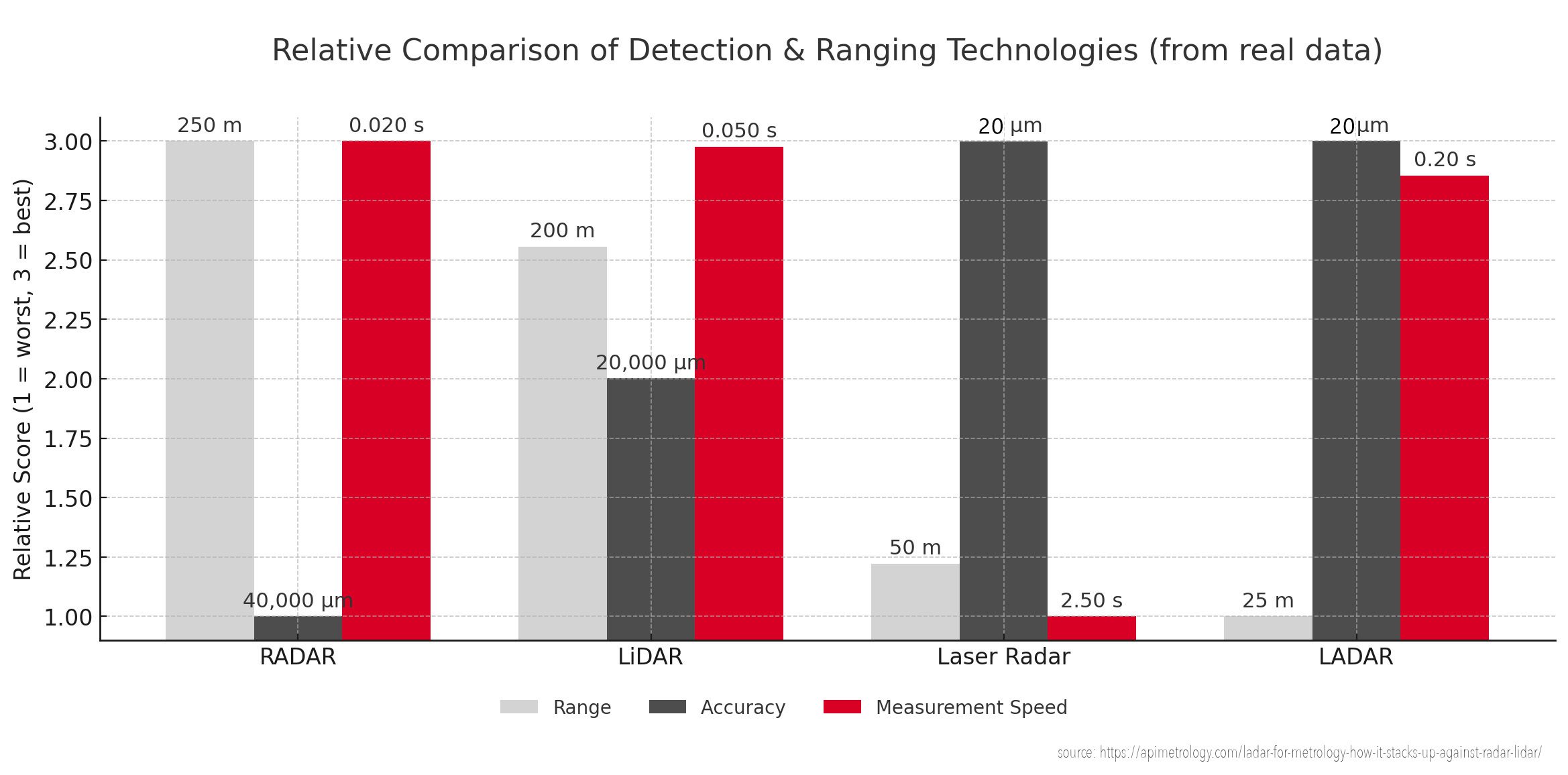

– Radar

Radar (Radio Detection and Ranging) emits microwave pulses and measures the time for echoes to return. Because radio waves have long wavelengths, radar devices can detect objects at great distances and through fog, rain or dust. They are widely used in aviation, weather monitoring and speed‑enforcement. Radar systems provide a long range but lower spatial resolution compared with LiDAR . This lower resolution arises from the larger wavelength and beam divergence; as a result radar cannot pinpoint features smaller than several centimetres.

(source:wevolver.com)

– LiDAR

LiDAR (Light Detection and Ranging) uses pulsed laser light to measure distance. Because it operates at optical wavelengths, LiDAR can produce very high‑resolution 3D point clouds. It is the backbone of autonomous vehicles and aerial mapping. LiDAR systems generally have a shorter to medium range but offer high spatial resolution, enabling detailed 3D mapping

LiDAR’s ability to capture millions of points quickly makes it ideal for applications such as autonomous driving and surveying. For manufacturing metrology, LiDAR is useful for creating digital twins of large objects or structures. However, typical LiDAR accuracy (millimetre to sub‑millimetre) is not sufficient for tight‑tolerance inspections that require micron‑level precision. Therefore, LiDAR still falls short for high‑precision metrology in aerospace and automotive manufacturing.

– Laser Radar

Laser radar is often used to describe high‑precision laser time‑of‑flight systems. It uses a narrow, focused laser beam and measures not only the time of flight but also the angles of the incoming beam to compute precise coordinates. Laser radar systems can achieve micron‑level precision but typically operate over shorter ranges and at slower scanning speeds compared with LiDAR. Laser radar system steers a focused beam, reading the return signal directly from the object without a retroreflector, and is engineered to provide precise, industrial measurements with tolerances of thousandths or even tenths of thousandths of an inch. However, the speed of data collection is sacrificed for resolution—laser radar scans smaller areas more slowly to achieve high accuracy

(source:eastcoastmetrology.com)

– LADAR (Dynamic 9D LADAR by API)

LADAR (Laser Detection And Ranging) is sometimes used interchangeably with LiDAR, but API’s Dynamic 9D LADAR is a novel system that blends interferometry with laser scanning. LADAR is an interferometry‑based non‑contact measurement system that provides fast and accurate data acquisition. It overcomes several limitations of conventional measurement methods by delivering micron‑level resolution and eliminating issues such as limited accuracy, slow data acquisition speeds and sensitivity to surface reflectivity. LADAR technology uses fast data acquisition to deliver rapid, real‑time data collection, significantly reducing measurement and analysis time compared with traditional methods. It also functions effectively in noisy production environments and at various incident angles. The technology delivers rapid, real‑time data collection, making it suitable for in‑line production measurements where conventional laser radar is too slow.