API SERVICES ARE AVAILABLE WORLDWIDE

MACHINE TOOL CALIBRATION

API reverse engineering service utilizes advanced equipment and software. Your facility or ours. API has perfected an efficient reverse engineering and modelling process.

“Review your reverse engineering project with the experts.”

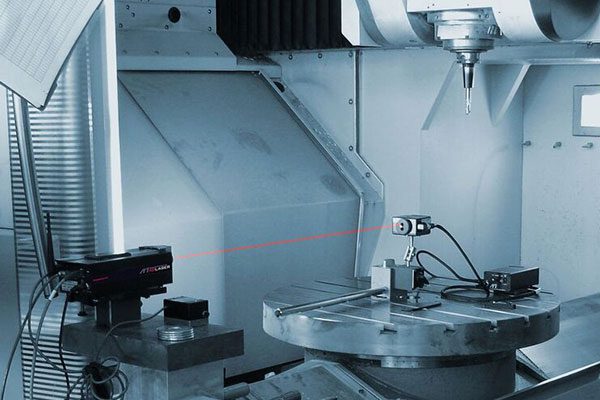

LASER ALIGNMENT

Machine tools depends upon precision alignment to produce accurate parts, reduce tool wear, extend machinery life and ultimately to increase your profitability. Lets API deliver your optimum machinery performance.

VOLUMETRIC COMPENSATION

RAIL ALIGMENT

EXPERIENCE MATTERS

- • Aerospace

- • Automotive

- • Heavy Machinery

- • Energy

- • Military & Defense

- • Manufacturing

- • Transportation

- • Machine Tools

- • Industrial Robots

API Measurement Services offer on-site prototype, 1st article and production measurements. Our suite of engineering services include reverse engineering and modelling, inspection and alignments, calibration services.

A2LA ISO 17025 certified.