API SERVICES ARE AVAILABLE WORLDWIDE

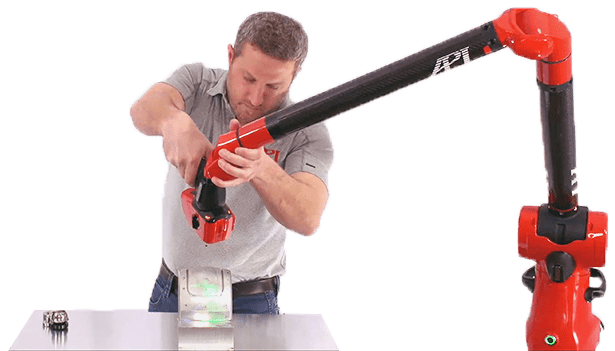

PROTOTYPE MEASUREMENT

On-site measurement service for prototype parts using laser tracker for large volume parts or portable arm CMM with optional laser scanning for smaller parts. Point cloud generation and full part modelling is available. API measurement services is an ISO 17025 certified organization, accredited by A2LA, our 3rd party prototype inspection reports provide the necessary confidence demanded by your customers.

API reverse engineering service utilizes advanced equipment and software. Your facility or ours. API has perfected an efficient reverse engineering and modelling process.

“Review your reverse engineering project with the experts.”

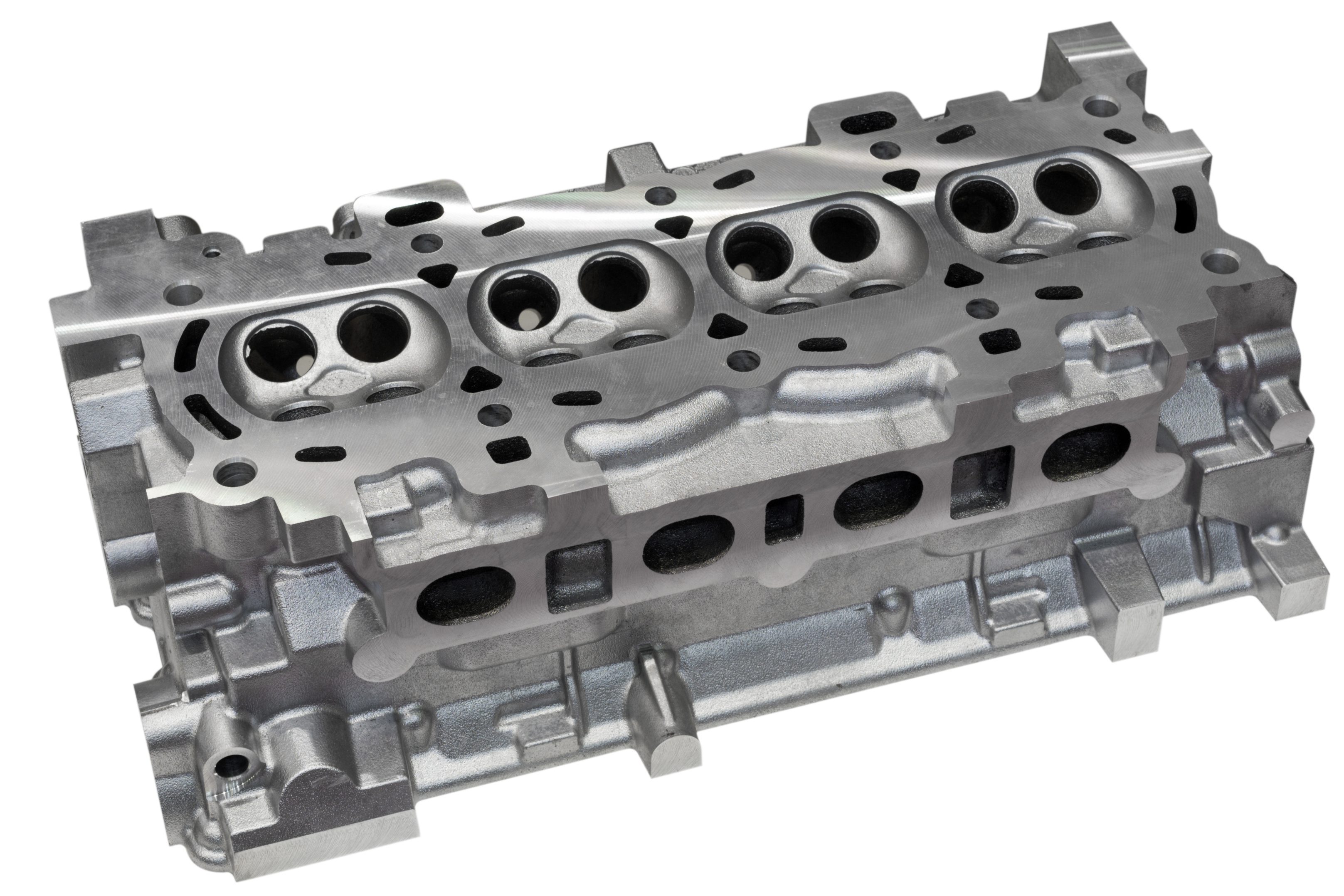

PROTOTYPE PARTS

Prototype part validation is a cornerstone event in the design and manufacturing cycle of a new product introduction. Inaccurate prototype validation can cause delays and cost overruns in the development cycle. API measurement services can provide accurate and accredited prototype part validation and provide 3rd party vendor assessments. Contract the experienced API measurement services team to provide the assurances necessary to your prototyping process.

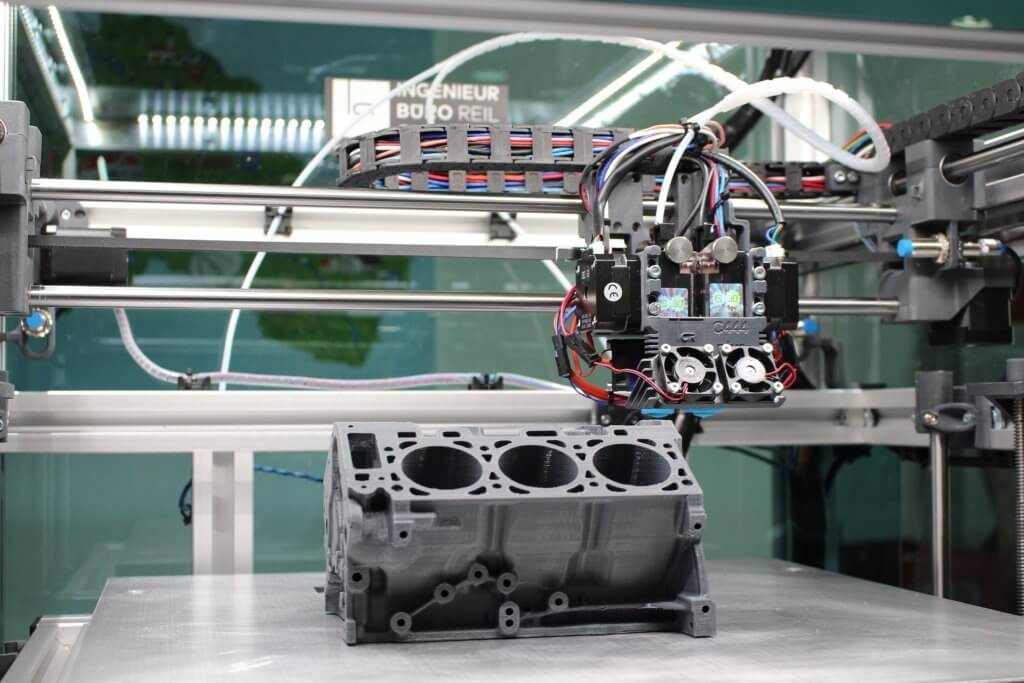

3D PRINTED PARTS

Rapid prototyping using 3D printing techniques reduces time to market for new product introductions by eliminating delays while awaiting tooling. The 3D printing process however can introduce signification errors into part geometry when compared to the original design intent. API measurement services can scan your 3D printed prototype parts allowing a full understanding of geometry deviations and provide a morphed CAD model to allow enhanced accuracy 3D part printing.

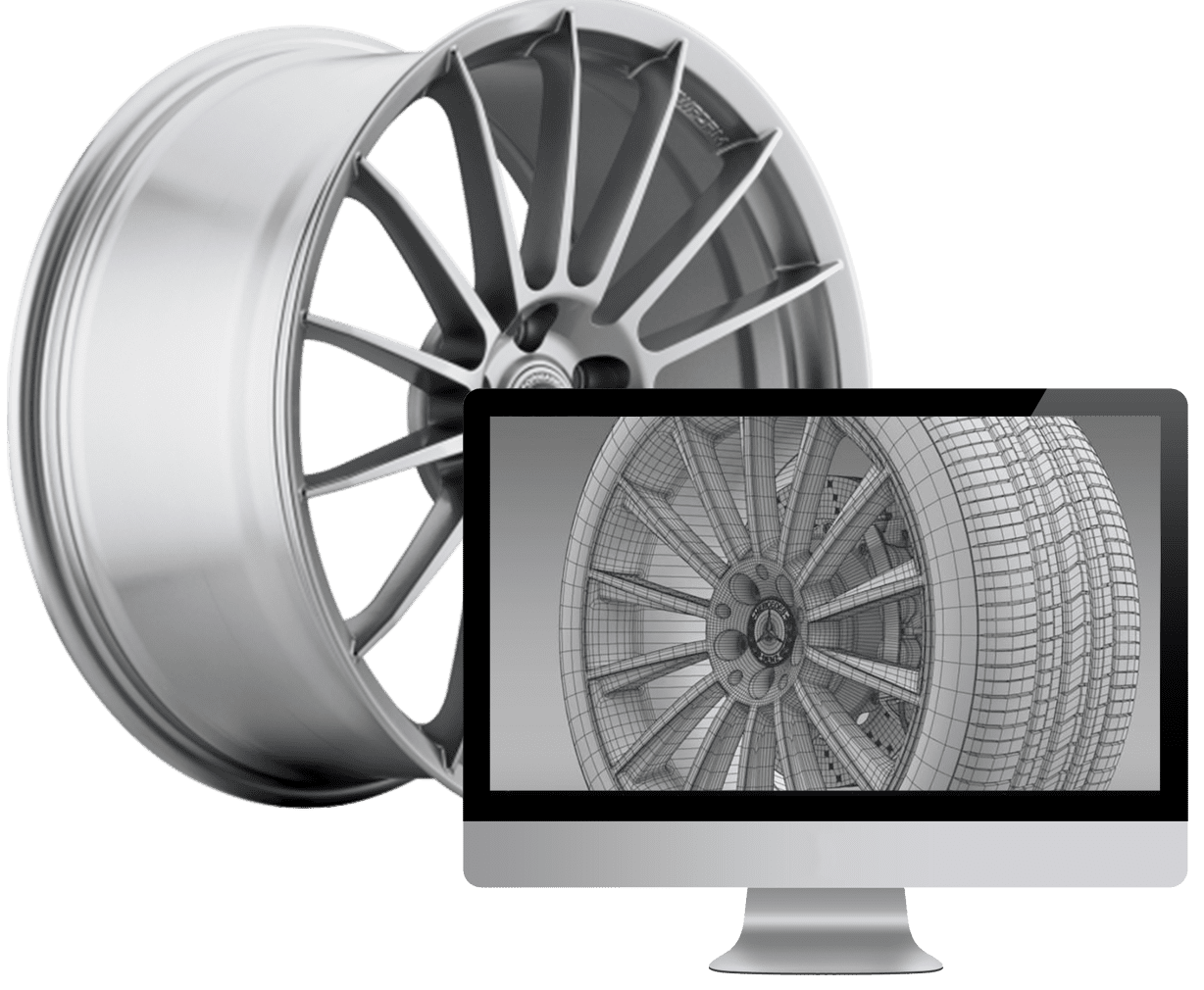

REVERSED ENGINEERED

In today’s global digital manufacturing economy many prototype parts are created from a reverse engineering process. Whether your requirement is a CAD model of a prototype part or designing a part within existing part constraints, API’s laser scanning services can provide a digital point cloud of your part with necessary detail and accuracy required by your project. Let API become your accredited external measurement services partner.

PRE-PRODUCTION

Many high volume manufacturing organizations run a pre-production series of parts through their manufacturing operation to validate tooling, equipment and process. API are experienced in performing real-time dimensional part validation and performing route-cause analysis through interrogation of the various production components. API technicians are available to support your needs on-site or that of a 3rd party supplier.

EXPERIENCE MATTERS

API Measurement Services are active globally across all manufacturing industries with specific measurement and calibration solutions per sector. API calibration equipment and services assist in improving manufacturing processes through the calibration of machine tools and the accuracy enhancement of industrial robots, both at original equipment manufacturers, and end users. API contract inspection services offer on-site prototype, first article, production measurements and a portfolio of reverse engineering, laser scanning and modeling services. API laser tracker inspection, alignment and measurement services, along with tracker rental programs, are active in the construction of new manufacturing facilities whether associated with building construction, equipment installation or aiding pre-production product manufacturing.

- • Aerospace

- • Automotive

- • Heavy Machinery

- • Energy

- • Military & Defense

- • Manufacturing

- • Transportation

- • Machine Tools

- • Industrial Robots

API Measurement Services offer on-site prototype, 1st article and production measurements. Our suite of engineering services include reverse engineering and modelling, inspection and alignments, calibration services.

A2LA ISO 17025 certified.