API SPINDLE ANALIZER

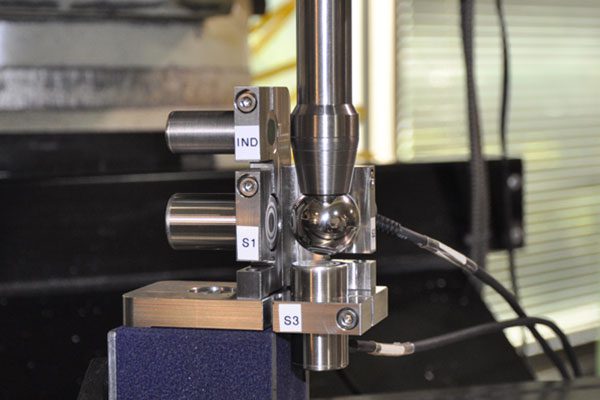

CNC SPINDLE ANALYSIS

256,00 HZ

SAMPLING RATE

5 DOF

MEASUREMENT

0.0005 MM

DISPLACEMENT ACCURACY

ASME B89.3.4

CERTIFIED & COMPLIANT

Reduce Costs

REAL-TIME DATA

DYNAMIC INSPECTION

CONTACT

Phone: 1-800-537-2720

FEATURES AND BENEFITS

REDUCE MAINTENANCE TIME

Save time by simultaneously collecting data in X, Y, and Z at full spindle Rotations Per Minute (RPM).

DYNAMIC SPINDLE MEASUREMENTS

Measures the total error motion of the spindle rapidly and identifies vibration, structural, and alignment error components to enable precise corrections.

LONG-TERM SPINDLE STABILITY

Measures spindle stability over time and enables the corrective action needed to compensate for the variance in thermal growth of the machine.

USER-FRIENDLY SOFTWARE

Software provides live data feedback, greatly speeding up the setup and alignment of the Spindle Analyzer. The ASME B89.3.4 compliant reports are easy to read and interpret.

FLEXIBILITY

Offered in Dynamic, Thermal or Combo models. Measurements can be taken in dynamic or stability modes, providing a solution for every operating need.

TECHNICAL SPESIFICATIONS

SPINDLE Analyzer SPECIFICATIONS

| Parameter | Specification |

| Sampling Rate | 256,000 Hz |

| Displacement Accuracy | ± 0.5 μm |

| Max Revolution | 20,000 RPM |

| Resolution | 0.1 μm (4.0 μin) |

| Measurement Range | 0-0.7 mm (0-0.03 in) |

| Thermal Drift | less than 1% per degree |

| Air Temp. sensor accuracy | ± 0.2ºC |

| Material sensor accuracy | ± 0.1ºC |

APPLICATIONS

Spindle Analyzer diagnoses machine tool spindle error and is available in three models. The Dynamic model rapidly measures rotational error motion. Thermal model measures spindle stability of the machine in 5 degrees of freedom (X,Y,Z axis + pitch and yaw) along with thermal variance. A combination model is also available. Measurements include:

- Speed Verification

- Check Bearings

- Rotational Errors

- Radial & Axial Errors

- Machine Repeatability

- Machine Vibrations

- Thermal Drift

- Thermal Error Mapping