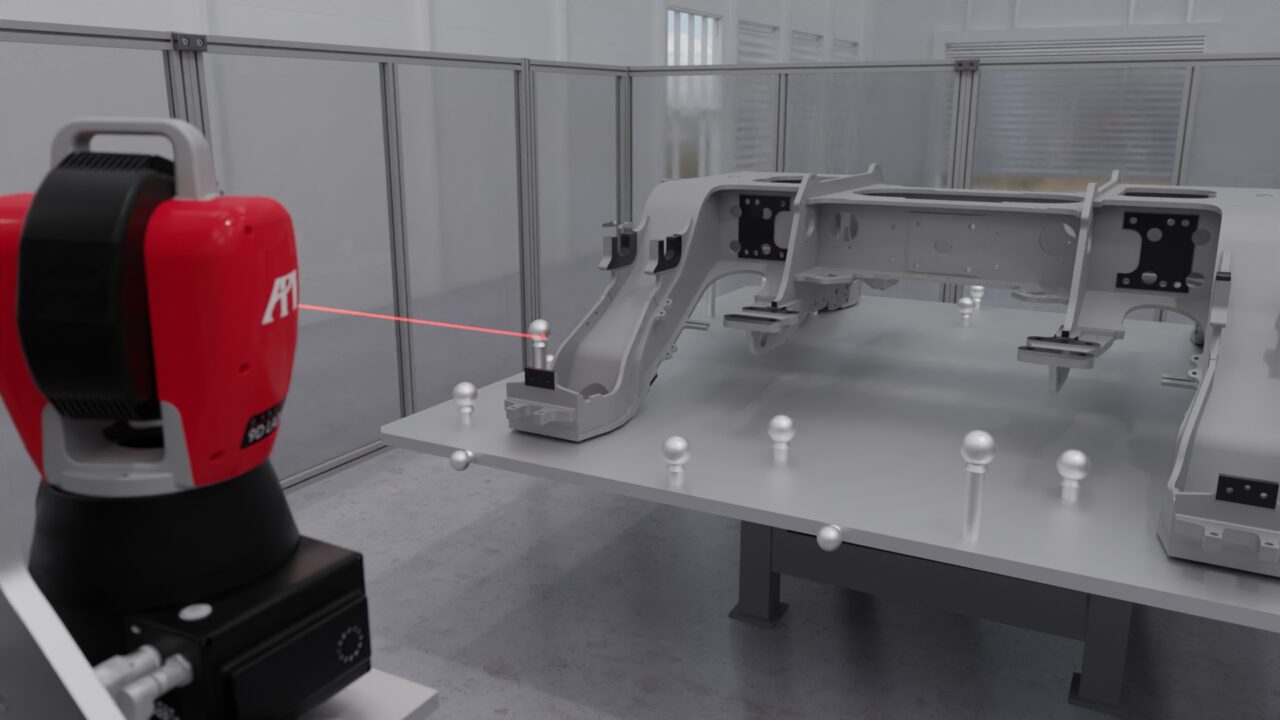

API’s 9D LADAR Revolutionizes Shop Floor 3D Inspections

In today’s manufacturing industry, high demands for precision and efficiency are driving the need for more automation, especially for time-consuming quality inspection and quality control processes. To help manufacturers keep up with these demands, API has been developing a series of flexible automation solutions that combine our state-of-the-art measurement equipment with integration to the leading software and robotics platforms to meet the varied needs of each industry. One such setup that is set to revolutionize shop floor 3D inspections uses Dynamic 9D LADAR on a vertical riser in a rotary table automation cell. With its integration into a rotary station and vertical positioning system, the setup allows for full 6 AXIS movement and offers numerous advantages that improve accuracy, speed, and cost-effectiveness.

One of the most significant advantages of the API Dynamic 9D LADAR is its iVision system. This system allows for easy point-click-and-measure checks, which enables the cell to quickly give results in a manual mode. This system eliminates the need for robotic teach pendants, which in turn reduces programming time by over 60%. This means that manufacturers can significantly reduce the time and resources required to program the automation cell, which results in faster production and lower costs.

Additionally, in a 7500mm cell, the LD8 (8 meter LADAR range) eliminates cumbersome robotic movements, which contributes to its high accuracy. With CMM accuracy and absolute accuracy for shop floor or in-process metrology, manufacturers can be assured of high precision measurements that meet their specific requirements. This accuracy is critical in industries such as aerospace and medical, where precision is of utmost importance.

Furthermore, the fully-enabled 6 AXIS movement allows manufacturers to perform inspections and measurements from all angles, which can help to identify potential issues that may be missed using other methods. This feature also contributes to the speed and efficiency of the cell, allowing manufacturers to produce products faster without sacrificing accuracy. And 9D LADAR’s ability to capture 20,000 points per second and perform tooling ball tie-in without needing to re-home after each measurement creates an automated setup that is more than 20x faster than traditional laser radar systems.

In conclusion, API’s Dynamic 9D LADAR offers numerous advantages for non-contact scanning in a rotary table automation cell. With its I Vision system, high accuracy, full 6 AXIS movement, and 20,000 points per second data collection, it enables manufacturers to achieve precision and efficiency in their production processes. By reducing programming time and offering high accuracy measurements, API and 9D LADAR are helping manufacturers achieve success in today’s competitive market. Click here to learn more about LADAR or contact us to begin planning your automation solution with an API Metrologist today.