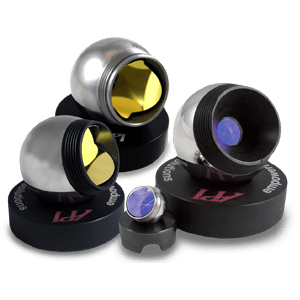

As we discussed previously on this blog, Spherically Mounted Retroreflectors (SMRs) are made up of three key components: the sphere, the corner-cube reflector, and the reflective coating on the reflector. Each of these components must be manufactured and assembled to extremely precise standards, which is why each one can be a source of SMR error. In this article, we discuss the main causes of SMR error in each component and how they can affect tracker performance.

The main cause of SMR error or inaccuracy for each component is damage. The most common form of damage for an SMR is from dropping, as it can affect the sphere, reflector, and coating. After any drop, the SMR should have its accuracy measured against another SMR to ensure proper operation. Damage, however, can also come through normal wear-and-tear to the SMR. And this kind of damage, and the resulting inaccuracy, can be much more difficult to notice.

Watch our video on SMR Inaccuracy.

Sphericity

The sphere, for instance, can fall out of grade if the same spot is repeatedly used across surfaces for point scanning (instead of traditional point measurement) without rotating. If you remember, the steel grade of the ball determines how spherical it is to within millionths of an inch. The slightest wearing away of a single spot of the ball can throw off this sphericity and make measurements inaccurate.

Corner-Cube Reflector

The corner-cube reflector can also be damaged through routine use. Over time, the adhesive that holds the three pieces of glass together can degrade. While this can lead to the reflector becoming dislodged from the sphere, the bigger concern is a subtle shift that changes the angle of the reflector. If this angle changes, it can affect the shape of the laser when it is reflected back to the tracker. This can lead to a host of errors, including total error where the beam is reflected out of shape that the tracker can read; adjacent angle error, which leads to runout errors when the tracker tries to find the center of the SMR; and wavefront distortion, where the panels are not perfectly flat.

Reflective Coating

Lastly, the reflective coating can be a cause of significant error through minor damage. Pinholes or micro scratches in the protective coating can create an opening that allows rapid oxidization and deterioration of the reflective metal coating. This is a bigger concern for silver coatings than gold, as we discussed previously. The reflective coating is also what is most affected by temperature changes. The accepted operating temperature for SMRs is much wider than that of the Laser Tracker, usually between -40oC-70oC, but beyond those temperatures, the results can be catastrophic for SMR performance. This is because the corner-cube and the reflective coating do not expand and contract at the same rate during temperature fluctuations, and the reflective coating can warp or separate entirely from the corner-cube under these conditions.

In short, SMR performance can be affected greatly by damage. Damage from drops is easy to notice, but SMR errors over time can go undiagnosed because it is easy to assume the issue is with the Tracker. It is important to always check SMR performance before measuring, and if the Tracker is reporting measurements out of specification, always double check the results with a different SMR to ensure the source of the inaccuracy. We cover the process for checking SMR performance and best practices in other parts of our SMR series.

Click here to learn more about SMRs or contact us and speak to a Real Metrologist today.