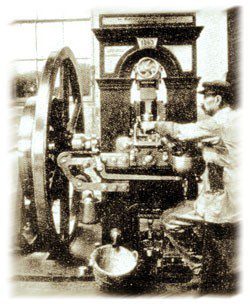

Did you know the first precision machine tool was made by John Wilkerson in 1775 for boring steam engine cylinders?

These initial machine tool were inspired by the invention of the steam engine and helped usher in the Industrial Revolution. Early machine tool designs were based on woodcutting lathes the had been used in France since the 16th Century. While the production speeds, volumes, and accuracies improved steadily over the following 200 years, the advent of Computer Numerical Control (CNC) systems for machine tools in the 1970s greatly improved production speeds and accuracies.

CNC and CAD improvements allowed for more complex and audacious designs in engineering projects around the world.

These CNC developments ran in tandem with improvements in Computer-Aided Design (CAD) files that could be edited on a computer and communicated directly to the machine tool. CNC and CAD improvements allowed for more complex and audacious designs in engineering projects around the world. Machine tools now produce more parts on tighter tolerances than ever before, and by 2017, global machine tool consumption had grown to a more that $80 billion industry.

To meet the demands of these projects, it has become more important than ever that machine shops keep their tools operating at their highest accuracies through routine calibration and maintenance. For some shops, this means owning and operating dimensional metrology equipment (like a laser interferometer or Ballbar), while for others, it means contracting a Metrology Service Provider (MSP) to perform the calibrations on site.

For more information on machine tools and the dimensional metrology equipment and people that calibrate them, click here to speak to a Real Metrologist today.