What is a Micron?

Microns are used by manufacturers, OEMs, and MSPs to discuss tolerances and capabilities. But how long have we been using the term, and how small are they actually?

What is a Micron? Watch the video below.

The term micron is everywhere in modern metrology. Manufacturers face tolerance demands in the microns; MSPs and OEMs promise accuracies within a few microns; and it’s even become the namesake of some computer and medical device companies. Micron is a very popular buzzword, but how long have we been using the micron as a guideline, what is a micron, and just how small is it?

Micrometer to Micron | mm to Micron

Micron is actually short for micrometer, which is the official unit of measurement. Micron was accepted as shorthand for micrometer in 1879 along with the symbol μ. The name and symbol, however, were revoked by the International System of Units in 1967. While the μ symbol has been abandoned in favor of μm, the micron itself has remained in use colloquially and officially in various industries since. In America, this is primarily to avoid confusion between micrometer and micrometer, the measuring instrument, in written language.

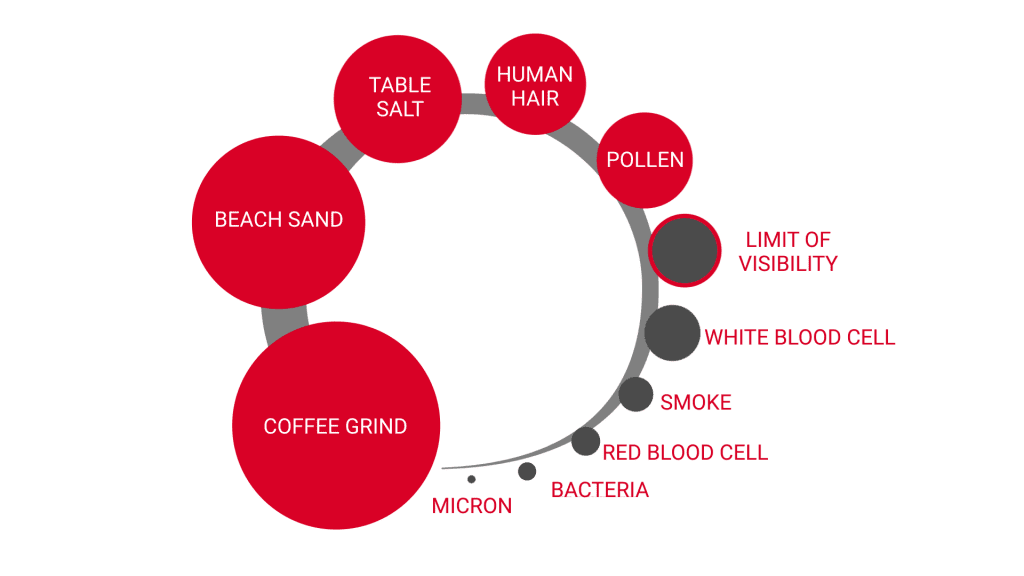

Put simply, a micron is one millionth of a meter, or .000001 meters. It can also be expressed as a thousandth of a millimeter or 39 millionths of an inch. There are plenty of size comparisons that can be found online, like this chart that shows how a micron is smaller than even bacteria, which are typically about 5 microns. As you can see, microns are well below the limit of visibility, which means that some of the tolerances being measured in today’s manufacturing are too small to be seen by the human eye.

“Like the chart shows, even a hair is 50-100 times the size of a micron. Meaning for measurements that call for 25 micron accuracy, we’re literally splitting hairs.”

Blade-Tech, Manufacturing Skate Blades.

Jeff: We manufacture our skate blades to .115in. We have a tolerance of +/- .001, so we can make the blades to .114 or .116in. Although, this tolerance may be different from other industries like Aerospace or Automotive, where they’re looking at things in the microns, this tolerance of ours of .115 +/- .001 is important and works well for the skating world.

Daniel: And the top sides of the blades are manufactured to equally challenging standards, as they’re designed to be changed rapidly in-game.

Jeff: That’s correct. So, when the blade is going to go up and into the holder, if we’re out of tolerance on the high side, where the blade is too thick or too large, it’s going to be a problem getting it up and in, and take a longer time to get it out; it could jam. On the other side, if the blade is too thin, or under tolerance, on the low side, it’ll go in the holder easily, but there might be too much room in there, and some lateral side slop and the blade can rattle around. And that’s not good either, because then our players are losing performance, efficiency, and power, and they’re not getting that reliability that they need. So, sticking to this tolerance, making sure that we manufacture to our CAD models and be consistent is what we need to do to provide our players the best performance.

Micron Measurement

Other industries require much tighter tolerances, however, from parts as large as airplane wings or as small as medical implant devices. The dimensions and features of these parts must all be manufactured accurately within a few microns. And just as importantly, the inspection processes on these parts must be accurate to those same demands, to ensure the models and machines producing the parts are accurate and repeatable across multiple runs of the same part. Laser Trackers, Laser-line scanners, and Coordinate Measuring Machines (CMM)s are just some of the methods for high precision inspection in modern manufacturing,

Want to learn more about Metrology?

You can read more educational blog post about metrology like this post by clicking here. Also make sure to watch our other educational video like What is 6 Degreese of Freedom on our Youtube Channel