Virtual Assembly Using Measured Data Aids Aircraft Wing Assembly

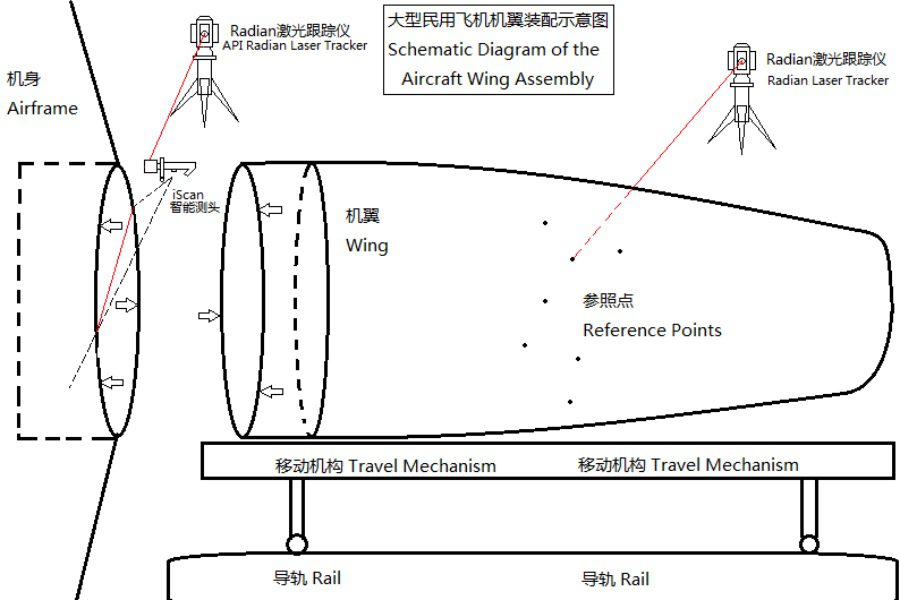

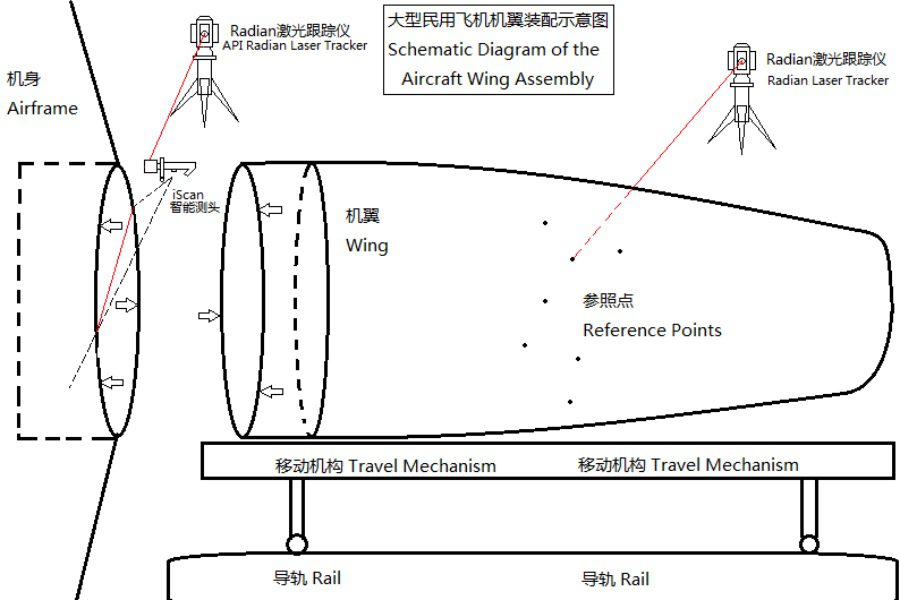

API Radian 6 Degrees of Freedom Laser Tracker, combined with laser scanning, provides critical fitting data in advance of physical wing assembly at aircraft manufacturer.

Aircraft wings are one of the most important components of an aircraft structure with their principle function being to generate lift. Wings have streamlined cross-sections that are subject to aerodynamic forces and act as airfoils. The aircraft wing is also used to carry key components including jet engines and landing gear. Moreover, the aileron, which is raised or lowered in order to control the aircraft’s in-flight movement, is also attached onto the wing. The wing is of such importance that extremely strict accuracy requirements during the critical wing assembly operation are demanded.

API was approached by a Chinese aircraft manufacturer to ascertain how its measurement technology could assist in ensuring the required high-level of accuracy in wing assembly, while also making the complex assembly task more efficient.

After extensive trials, API’s breakthrough multifunctional iScan measurement tool was selected by the aircraft manufacturer. iScan was used, in combination with the API RADIAN 6DoF laser tracker, offering both tactile probing measurement and laser scanning in a combined unit. iScan can measure difficult to access features by using a 100mm length styli and can perform both geometry measurements and deliver surface topology using the 3D laser scan function. The unique 360°iScan head rotation provides considerable user convenience allowing the scanning of the complete airframe and wing without needing to relocate the Laser Tracker.

The process adopted by the aircraft manufacturer using RADIAN and iScan to ensure wing assembly accuracy and improve assembly efficiency was as follows:

- Establish aircraft coordinate system using measurements taken with RADIAN.

- Confirm non-interference of the geometries of both the joints of the airframe and wings using the iScan sensor to scan the mating surfaces while using the generated data to calculate physical errors and tolerance compliance.

- Virtual assembly. If the joint geometries were calculated to be within acceptable parameters, the generated scan data is further processed in the metrology software to create a new coordinate transformation matrix.

- Physical Assembly: The matched data on selected reference points is used to guide the actual wing to fuselage assembly operation.

API support its Chinese customers directly through its subsidiary operation with facilities in Shanghai, Beijing and Chengdu, China.