What is Calibration?

Laser Trackers naturally see an erosion in their performance over time. Wear and tear from regular use, plus a host of environmental factors, can create slippage in accuracy. Fortunately, there are many ways to test your Laser Tracker to determine whether it is fit for service.

The most common term that is used for Laser Tracker testing is Calibration. Tracker OEMs and many Metrology Service Providers (MSP) offer Laser Tracker Calibration. But Calibration is actually a very specific term, relating to a set of validation tests and performance corrections. Many of the checks done by Tracker operators and MSPs fit into different categories like Compensation, Verification, and Certification, and each process is important to maintaining Tracker performance. So, what is Calibration? How does it differ from the other methods? And how do you know when your Tracker is actually being calibrated or needs to be? Let’s take a look.

Watch The Video!

Calibration is the most comprehensive way to guarantee Laser Tracker performance. Traditionally, full calibration can only be performed by the OEM because they have proprietary knowledge of the internal mechanisms, firmware, software, and calibration values of the Tracker. This is important because Calibration, as defined by the International Vocabulary of Metrology (VIM), is a two-step process.

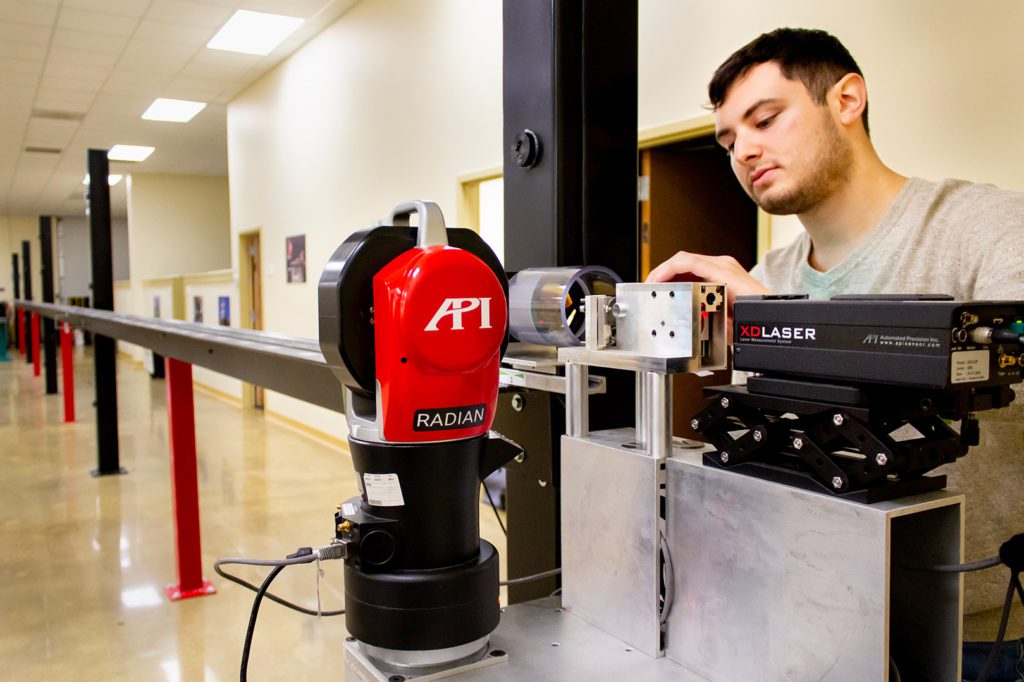

The first step is to “establish a relation between the quantity values with measurement uncertainties provided by measurement standards,” which simply means that the Tracker’s current performance is evaluated against some kind of reference standard (usually a laser rail and interferometer). ISO 17025, NIST.IR.8016, and ASME B89.4.19 all establish reference standards against which Trackers can be compared.

These standards (along with published OEM specifications) can be used for Verification and Certification of Laser Tracker performance. This process alone only evaluates the current performance of the tracker, and for Certification and Verification, provides the Tracker with a pass/fail certificate. It cannot, however, correct any errors that are found in Tracker performance.

Correction happens in the second defined step of Calibration. The second step “uses this information to establish a relation for obtaining a measurement result from an indication,” which means that Calibration uses the information gathered in step one to identify where Tracker errors are occurring and make the necessary corrections or repairs to return the Tracker to optimal performance.

This second step is unique to Calibration and is the only way to use the data gathered in Step 1 to improve tracker performance. The VIM includes notes to specify this, saying that Calibration should not be confused with small Compensation efforts (like 1 or 4-point QVC) or Verification, and that the first step alone is often perceived as Calibration.

To visualize the differences between Verification, Certification, and Calibration in a different way, let’s compare them to how we examine and correct our vision. Often people are unaware that vision problems are developing, because our brains compensate for subtle changes in visual processing. But that doesn’t correct the long-term errors, and they eventually need to come in for an eye exam. Tests like the eye chart and phoropter, for example, serve as the Verification and Certification stages of this exam. They evaluate your vision performance against a standard and help identify where issues are taking place. Lastly, corrective lenses or LASIK surgery Calibrate vision to correct errors at the source. And much like a Laser Tracker, people who wear glasses need to return to the Optometrist regularly to have their prescription Calibrated as vision performance changes. In short, Calibration is the two-step process of evaluating Tracker performance against a reference standard and, most importantly, using that information to make improvements to the Tracker’s performance. Verification and Certification tests only perform the first part of this evaluation without

correcting error sources. Compensations can temporarily offset Tracker error without identifying the source of the issue.

If your service provider is only performing the evaluation measurement, then your Tracker is not receiving full calibration, which usually needs to be performed by the OEM. Full calibration is recommended yearly for all Laser Trackers, and we discuss the reasons why in our 7 Reasons to Calibrate Your Laser Tracker Today video.

The team of experienced metrologists at API Services are available for Laser Tracker Certifications of all brands both on site and at our service centers across North America and Globally. And All API Trackers can receive full calibrations to B89 Standard at our calibration labs. Visit services.apimetrology.com to learn more.