API: Measurement Equipment and Services, Provided by Globally-Local, Expert Metrologists for your Manufacturing and Inspection needs.

Whether you need to inspect a part or calibrate your Laser Tracker, API Metrology has the best products on the market and the most knowledgeable staff of expert metrologists.

API now offers both on site and online virtual demos for you to get to know us and our products.

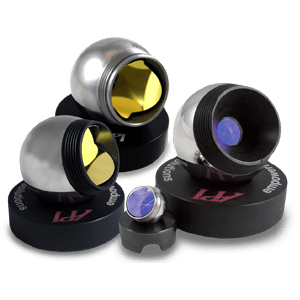

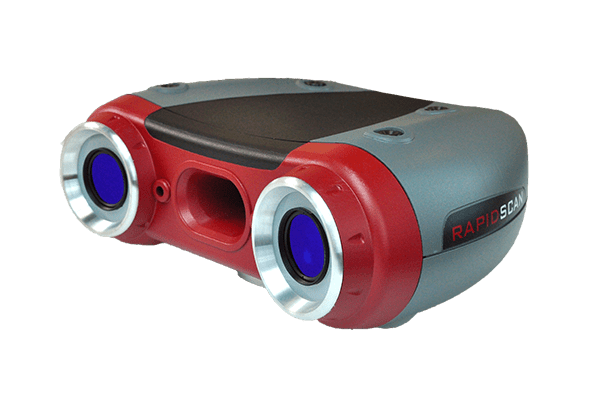

MEASUREMENT & CALIBRATION EQUIPMENT

“dimensional measurement & manufacturing process optimization”

MEASUREMENT & CALIBRATION SERVICES

“API also provides ISO 17025 accredited portable metrology inspection and calibration services”

API METROLOGY SERVICES can help with every step in the manufacturing process. We can scan a prototype part to create a model for mass production, inspect the first pieces off the production line to ensure accuracy, do spot checks throughout the manufacturing process to maintain repeatability, reverse engineer old parts to return them to production, and calibrate machine tools to check for inaccuracies and help compensate for their errors. At our Globally-Local Calibration Labs, we not only calibrate API’s Radian Laser Tracker series, but we can even certify other tracker brands.